Air-Z Flex

Automated air displacement pipetting module available with or without control electronics and pressure sensor.

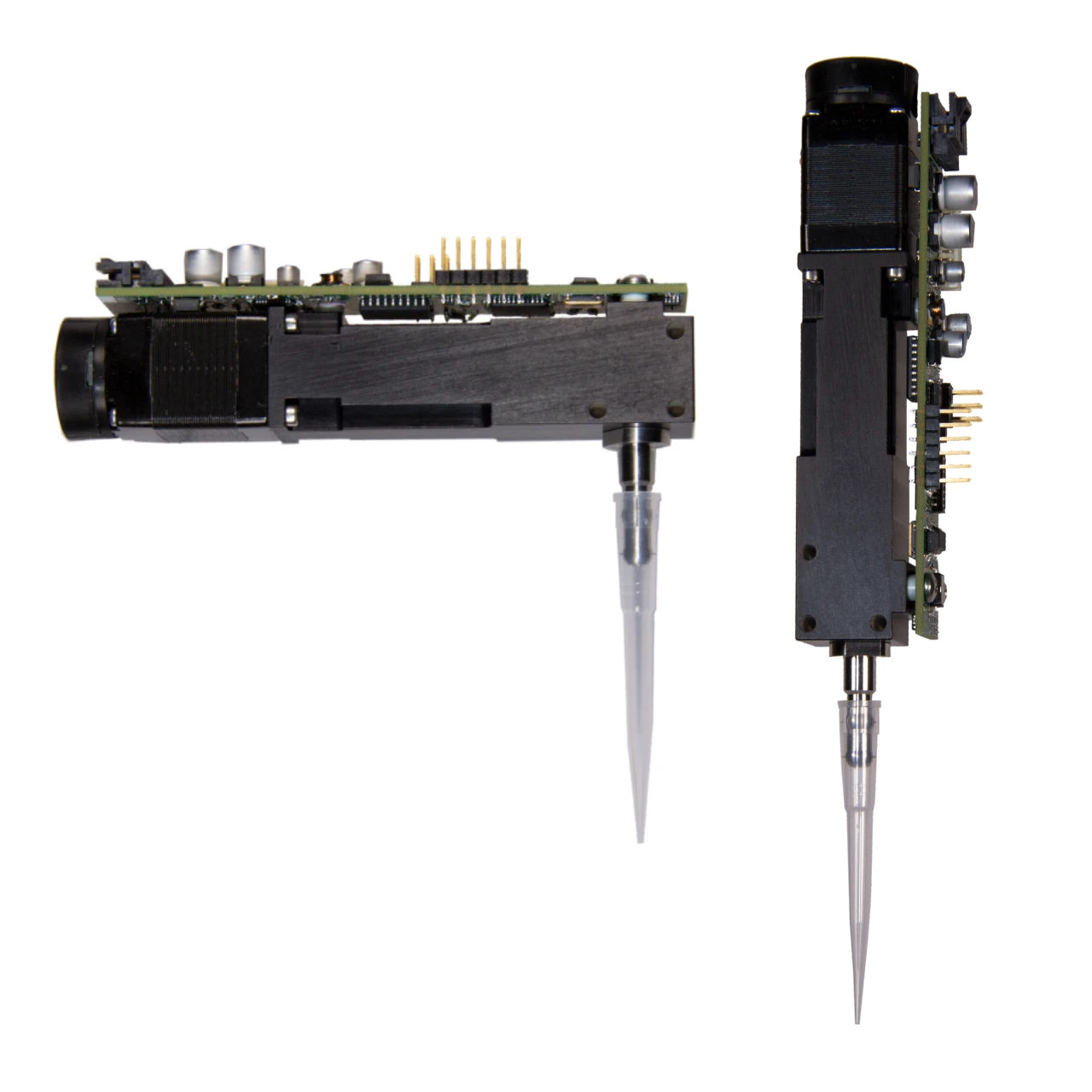

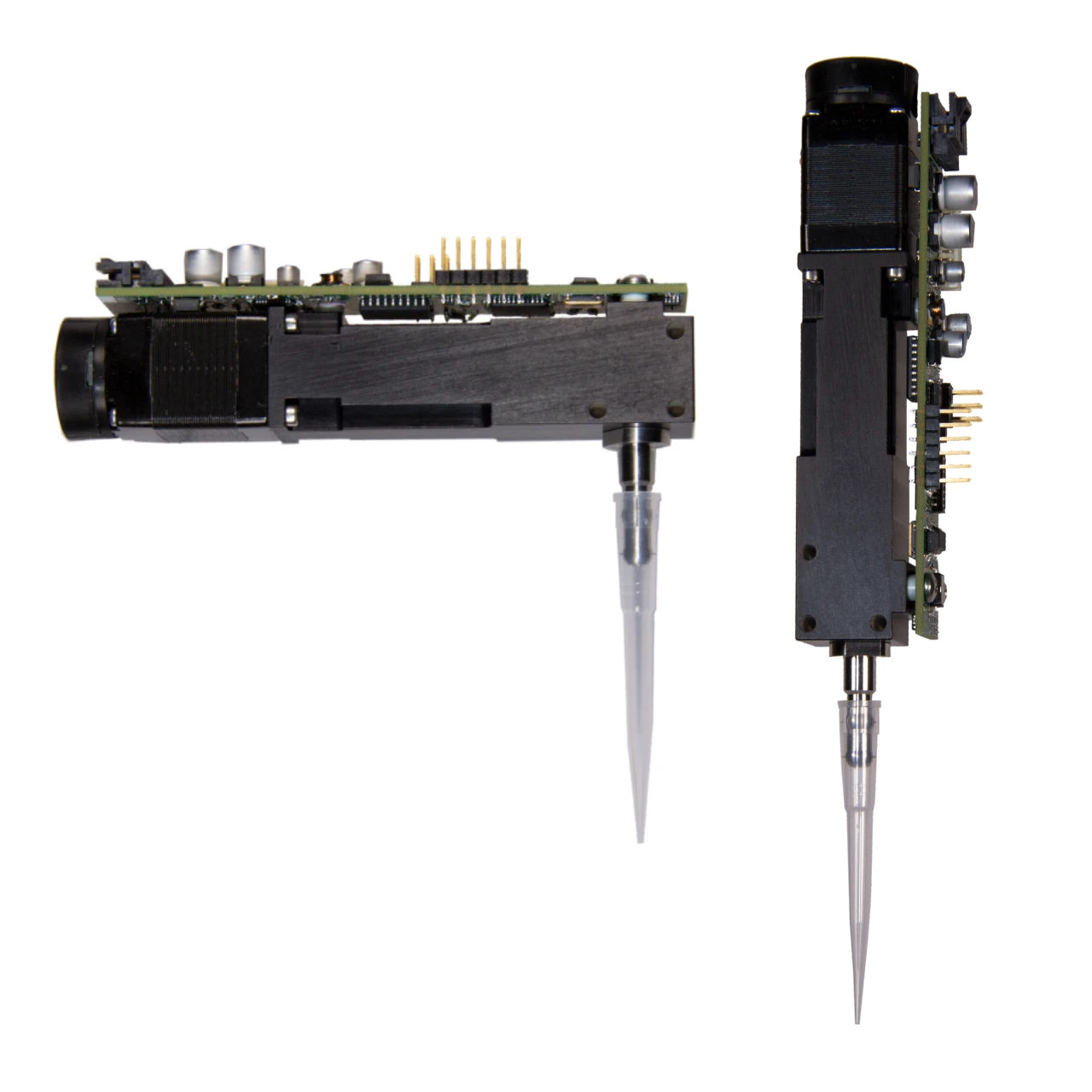

Automated air displacement pipetting module available with or without control electronics and pressure sensor.

TriContinent's first air displacement pipette with proven technology for use on liquid handling robotic systems.

Most economical model for low-duty cycle applications, designed for easy installation and replacement.

Fully-featured, fully programmable air-displacement pipetting module with integrated tip ejection and automatic detection of liquid levels, tips, tip blockage, step loss and more.

| Air-Z FEATURES | Air-Z Premier | Air-Z Flex | Air-Z Mini (available upon request) | Air-Z Legacy |

|---|---|---|---|---|

| High-resolution encoder (step loss detection) | ✓ | ✗ | ✗ | ✗ |

| Liquid level detection: pressure (pLLD) | ✓ | ✗ | ✗ | ✗ |

| Liquid level detection: capative & hybrid (cLLD & hLLD) | ✓ | ✗ | ✗ | ✗ |

| Real time streaming pressure data | ✓ | ✓ | ✗ | ✗ |

| Quiet at all speeds | ✓ | ✓ | ✓ | ✓ |

| Built-in tip ejector | ✓ | ✗ | ✗ | ✗ |

| Clogged tip detection | ✓ | Option | ✗ | ✗ |

| Fully programmable (w/control electronics) | ✓ | Option | ✗ | ✗ |

| Optional horizontal or vertical mounting orientation | ✗ | ✓ | ✗ | ✗ |

| Pump volume options | 1000 μl | 50 μl, 250 μl, 1000 μl | 50 μl | 20 μl, 1000 μl, 2000 μl, 5000 μl |

| Tip volume availability | 20 μl, 50 μl, 200 μl, 1000 μl | 20 μl, 50 μl, 200 μl, 1000 μl | 20 μl, 50 μl | 20 μl, 1000 μl, 2000 μl, 5000 μl |

| Overall dimensions without disposable tip (H x W x D) | 168.7 mm x 60.5 mm x 30.5 mm | 130.5 mm x 30.6 mm x 25.0 mm | 110.7 mm x 20.2 mm x 19 mm | 131 mm x 47 mm |